Boeing is one of the most innovative companies. They keep reinventing various parts of their aircrafts. This fits in with the innovative model practised at Boeing. Boeing’s CEO Jim McNerney disclosed their innovation philosophy, Boeings aims to emulate the product strategy of Apple Inc. by developing future passenger jets in incremental steps, rather than once-a-generation “moon shots” that carry too much risk.

So Boeing keeps improving all components of aircraft starting from the passenger seats to the engines. Last year, we discovered a patent from Boeing on cuddle seats.

Now, Boeing has filed a patent application on a new seating plan for aircrafts, that maximises the usage of space and also increases the safety of the passengers.

Optimizing the use of fuselage volume allows the aircraft to carry higher payloads of passengers and cargo. The ability to carry higher revenue payloads reduces operating expenses relative to revenue, while simultaneously reducing fuel burn per seat-kilometer, and also reducing CO2 production per seat. However, the challenge of optimizing the use of available fuselage volume is complicated by the need to provide for passenger comfort and safety while accommodating associated cargo requirements. Finally, passenger cabin layout and design must take into consideration the need for crash landing energy absorption in lower areas of the fuselage.

Two approaches that have been used in the past to increase passenger capacity of existing aircraft:

- Stretch the aircraft body, and

- Increase the passenger abreast count

The former approach keeps the ratio of the passenger seat count and cargo capacity roughly the same. Also it changes aircraft take-off and landing parameters, and sometimes involves a redesign of aircraft wings and the use of different engines. The latter approach can involve the use of narrower aircraft seats, which reduces passenger comfort, and can involve significant redesign of aircraft structural components. So both approaches have considerable drawbacks.

Therefore, Boeing has developed a fuselage design and cabin layout that optimizes use of the fuselage volume while satisfying the need for crash worthiness and cargo carrying requirements.

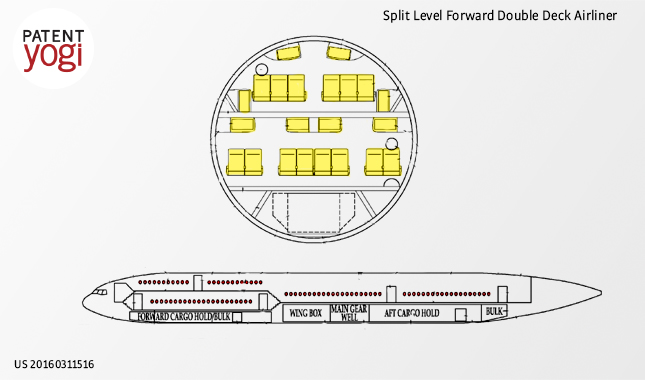

The design includes a split level cabin floor layout within a fuselage of uniform cross section. Cargo decks are included beneath passenger seating areas to provide crushable zones that absorb energy during crash landings in order to protect passengers. The split level cabin layout includes upper and lower stacked cabins connected to an intermediate level main cabin through stairs, elevators or escalators. Stairs connecting the main cabin to the upper and lower cabins are longitudinally spaced, as required, to accommodate underlying cargo bays and landing gear wheel wells. The space above the main cabin is utilized as a rest compartment for crews that is accessible by stairs or ladders. Further, the lower cabin is near the waterline of the aircraft, split “dutch” doors in the fuselage provide passenger egress while protecting against the inflow of water into the cabin in the event of an emergency water landing.

Publication number: US 20160311516

Patent Title: Split Level Forward Double Deck Airliner

Publication date: 27 Oct 2016

Filing date: 30 Jun 2016

Inventors: Mithra M.K.V. Sankrithi; Sergey D. Barmichev;

Original Assignee: The Boeing Company