Current 3D printing techniques employs a “bottoms-up” building method in which the part is built layer-by-layer on a supporting platform that moves down as the individual layers are formed. A single print head is moved around the platform to form each of the layers. Therefore, it is necessary to build the part on support materials which must be later removed from the 3D printed part. Moreover, the use of a single print head to form features of each layer renders the fabrication process relatively slow.

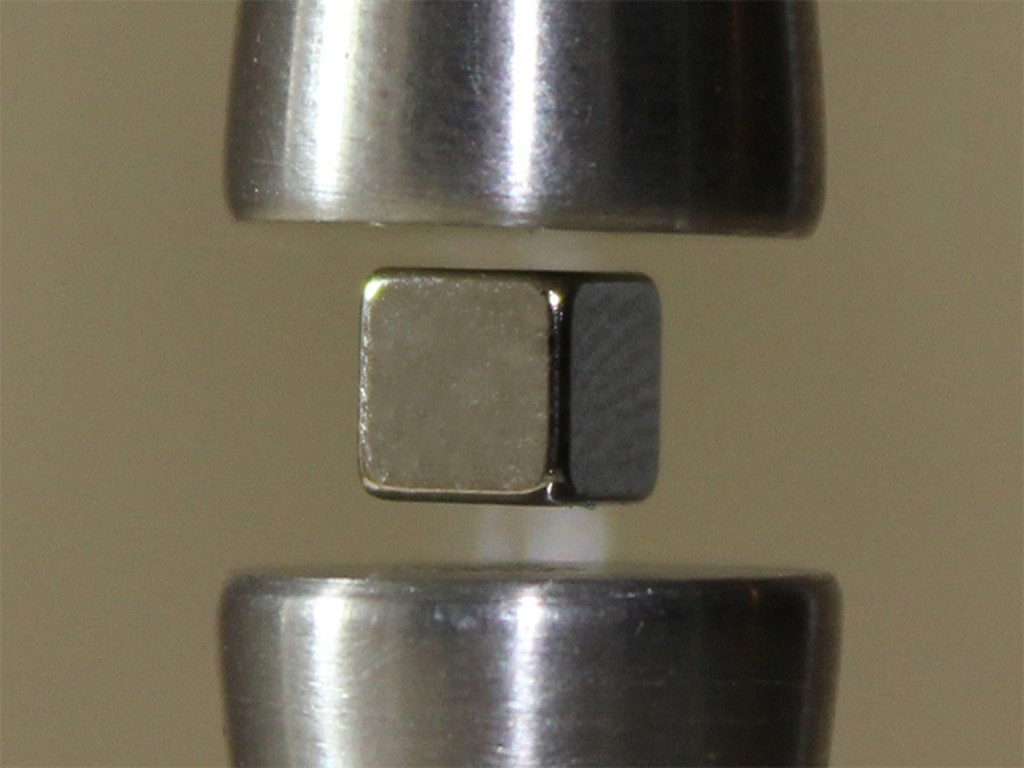

The patented technique allows free-form fabrication of three-dimensional parts. The part is levitated in space and can be moved or rotated to any angle in order to form desired features at any location on the part without the need for support structures to stabilize the part. Multiple print heads may be employed to simultaneously print features of the part, thereby increasing fabrication speed.

Patent Information

Publication number: US20160031156

Patent Title: Free-Form Spatial 3-D Printing Using Part Levitation

Publication type: Grant

Publication date: 4 Feb 2016

Filing date: 29 Jul 2014

Inventors: William A. Harkness; Josh H. Goldschmid;

Original Assignee: The Boeing Company