3D printing technology has made life a lot more convenient due to its vast applications. 3D printers can be used in various fields from constructing cars and buildings to its several medical applications. The first ever 3D printer was invented in 1981 by Hideo Kodama where the printers were used to create plastic models. In 2015, China constructed the world’s tallest 3D printed building which is a 5 story apartment block. This shows the advancement of technology over the time.

The major issue with the current 3D printing technology is that conventional 3D printers take a lot of time to print a 3D product. Also, since there are several movable parts involved, it can result in errors. Further, the movable parts wear and tear easily, so need to be changed from time to time. Boeing came up with the technology to overcome these problems.

PATENTED TECHNOLOGY

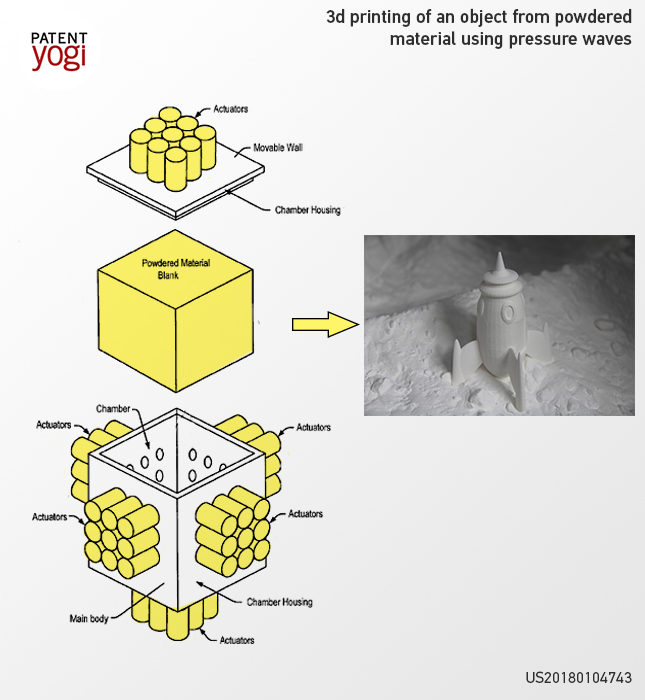

In April 2018, Boeing filed a patent about their new 3D printing technology where they use pressure waves to print 3D objects from powdered material. Unlike conventional 3D printers, Boeing’s invention does not have a movable platform or one or more sweep arms with moving print heads. Instead, it has an immovable container which is filled with powdered material. This container is covered by several housing chamber from all directions.

Any 3D model can be printed using this technology. The 3D model may include a mathematical model of the object, a computer-aided design (CAD) representation of the object, a numerical programming representation (G-Code) of the object or combinations thereof.

The chamber is deprived of any gases using a vacuum tube once the powdered material is placed inside it. Several actuators are activated together to create several pressure waves which interfere together to create regions of constructive and destructive interference. This interference solidifies the powdered material in certain regions to give us the desired object. The finished product is thus taken out from the container and the leftover powered material can be reused in future.

Since several actuators are operated together, many tasks can be done altogether. If a single actuator produces an error, then it can be easily rectified by several other actuators.

WHAT IS YOUR TAKE?

So what do you think about this new 3D printing technology? Let us know in the comments below.