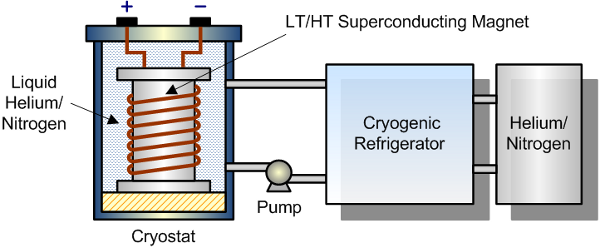

Superconducting magnetic energy storage (SMES) devices store energy in a magnetic field. SMES devices include a superconductor wound around a core, to form a coil, and at cryogenic temperatures the coil functions in a superconducting state. For example, the superconducting coil is cryogenically cooled bringing it into the superconducting state, such that the resistivity of the wire approaches zero (i.e., the coil has virtually no electrical resistance) and does not lose energy in the form of heat.

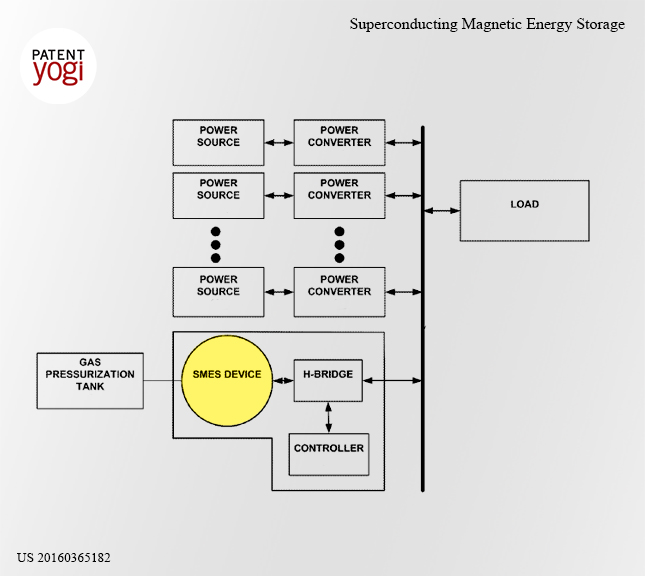

The SMES device operates in three modes set by the operation of power electronics equipment (e.g., a controller as described in more detail below). The SMES device stores energy in a magnetic field in a charge mode and a maintain mode, and dissipates the energy in a discharge mode. In a charge mode, current flows from a positive node to a negative node (or ground) via the winding of the SMES device. In a maintain mode, the current is diverted to circulate through the winding of the SMES device. In a discharge mode, the current is outputted to deliver power.

The flow of current through the winding during the charge mode creates a magnetic field. In the superconducting state, there is little loss in the current flowing through the winding meaning that the magnetic field is preserved in the maintain mode through the circulation of current in the winding. In this manner, the SMES device stores energy in a form of a magnetic field. Then, in the discharge mode, current flows out of the SMES device collapsing the magnetic field.

As a result, SMES devices allow virtually lossless energy storage in the superconducting state, while allowing for extremely fast charge and discharge capability. Because of these benefits of SMES devices, including the benefit that SMES devices function at cryogenic temperatures, SMES devices may be utilized to store relatively high amounts of energy and for rapid delivery of such energy.

SMES devices are typically cooled by bathing the SMES device in a tank of cryogenic fluid. The external tank of cryogenic fluid requires a large volume of space. Because space may be limited in potential SMES applications, the size of a SMES device and the energy stored in the SMES device is also limited.

Rolls Royce has invented improved SMES devices that reduce the total volume of space required to store a given amount of energy. The SMES device itself internally store the cryogenic fluid, rather than being placed in the tank of cryogenic fluid. Storing cryogenic fluid inside an SMES device reduces the physical space required by the SMES device because it does not require a tank of cryogenic fluid. Likewise, storing cryogenic fluid inside a SMES device allows use of a larger SMES in the same physical space that would otherwise be used by a tank of cryogenic fluid, thus storing more energy.

Further, in some examples, cryogenic chamber may be used as a fuel tank and cryogenic fluid may provide fuel to an engine or fuel cell. For example, SMES may act as a cryogenic fuel tank, storing liquid hydrogen in cryogenic chamber, such that the liquid hydrogen may fuel an engine. As a result, the liquid hydrogen may, in some examples, cool superconducting coil to a superconducting state in order to store energy in a magnetic field, while simultaneously providing fuel to an engine (e.g., load that is also in a superconducting state from the cooling from the liquid hydrogen). Thus, SMES may store two forms of energy (e.g., electromagnetic and fuel) in the same volume of space, which may allow for smaller fuel tanks or more energy storage in a given volume of space.

Publication number: US 20160365182

Patent Title: Superconducting Magnetic Energy Storage

Publication date: 15 Dec 2016

Filing date: 9 Jun 2016

Inventors: Michael James Armstrong;

Original Assignee: Rolls-Royce North American Technologies, Inc.