Ice formation on aircraft surfaces affects performance by increasing weight, creating drag, and loss of lift.

In general, icing can occur: 1) while the aircraft is on the ground prior to take-off at airports in cold regions during the winter months; and 2) while in-flight any time throughout the year.

Ground icing of aircraft usually results from freezing conditions that occur during frost, snow, and ice/freezing rain storms. Such events result in coverage of the entire aircraft with impregnation of control surfaces.

Impact icing (i.e. in-flight) occurs when supercooled water droplets impinge and freeze on aircraft surfaces in clouds at temperatures at or below freezing.

Current strategies used to alleviate icing problems involve pneumatic boots, heated surfaces, and deicing agents. Besides potential environmental concerns, ground application of deicing agents can impede efficient throughput of air traffic at airports during the winter months.

In comparison, the patented coating provides a passive approach that would be applied to the aircraft surface either as a topcoat or as a constituent of aircraft paint. The application frequency for these coatings would ideally conform with routine aircraft maintenance and painting schedules.

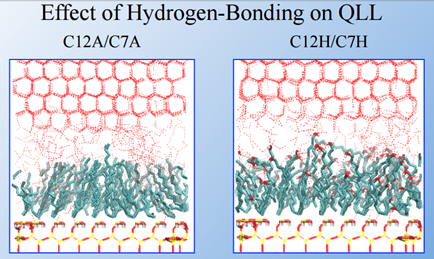

NASA scientists conducted an in-depth study to study ice formation. Specifically, they put in a combined effort of synthesis, characterization, and experimental evaluation along with molecular dynamics (MD) simulations to understand and develop ice mitigating surface coatings based on hydrogenbonding (HB) groups and molecular roughness.

They set a technical goal of developing surface modifying chemistries designed to mimic antifreeze protein behavior with respect to ice growth inhibition.

NASA scientists followed this technical approach to achieve their technical goal.

• Material synthesis and characterization of hydrogenbonding (HB) compounds.

• Preparation and characterization of coated Aluminium surfaces.

• Qualitative icing studies.

– Sub 0°C freezer.

– Microdroplet/Temperature Monitoring Device.

• MD simulations providing information with regards to coating-ice interactions.

This approach led to development of a coating that provides a passive approach that would mitigate ice adhesion during the entire aircraft flight profile thus improving safety, minimizing the use of environmentally unfriendly chemicals, and reducing operational complexity.

Specifically, the invented ice mitigating surface coatings are formed by hydrolysis of one or more substituted n-alkyldimethylalkoxysilanes terminated with functionalities having the following characteristics with respect to water: 1) non-polar interactions; 2) hydrogen bonding through donor and acceptor interactions; or 3) hydrogen bonding through acceptor interactions only.

Following figure shows how the invented coating (shown in green) works and creates a liquid layer between the metal and ice (shown in red).

Watch this video of NASA scientists explaining their project.

Publication number: US 20160177106

Patent Title: Hydrogen-Bonding Surfaces for Ice Mitigation

Publication date: Jun 23, 2016

Filing date: Dec 21, 2015

Inventors: Joseph G. SMITH, JR.; Christopher J. WOHL, JR.;

Original Assignee: U.S.A. as represented by the Administrator of the National Aeronautics and Space Administration