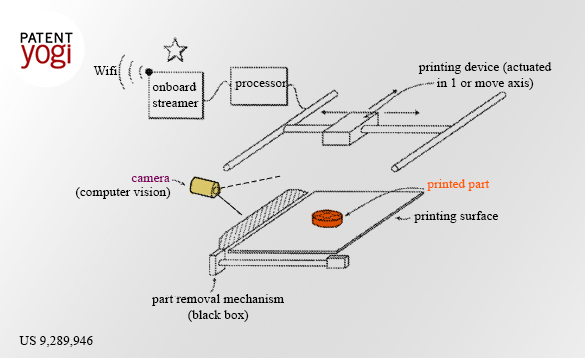

MIT has invented a 3D printer that is fully automated and takes fewer number of steps to print an object compared to existing 3D printers. This 3D printer also has the additional feature of correcting itself in the event of any printing errors.

While the object is being printed, a camera continuously monitors the object. Using machine vision, any deviation from the object’s model is detected and the print is identified as failed.

The 3D printer then proceeds to automatically remove the printed part and discard it before restarting the printing process.

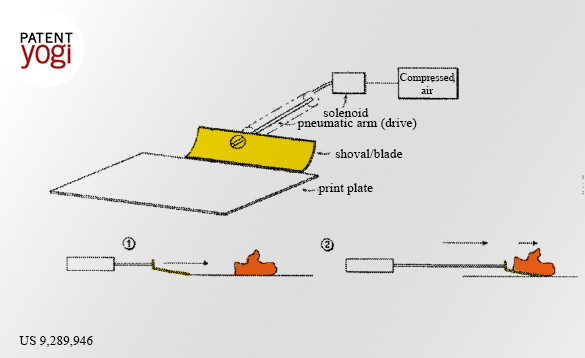

In order to automatically remove and discard the printed part, a motorized blade is used. A solenoid-controlled pneumatic piston moves the blade across the printing surface separating the printed part from the printing surface. The printed part is then disposed. The technique may also use other mechanisms of removal such as by vibrating the printing surface or using pins that rise from the printing surface from below and push the printed part away. The same mechanism may also be used to separate the final printed object thus avoiding need for any human intervention.

3D printing technology is indeed getting smarter. Here is a thumbs up to this technology.

Publication number: US 9289946

Patent Title: Automated three-dimensional printer part removal

Publication date: 22 Mar 2016

Filing date: 16 Jan 2014

Inventors: Alfonso Alexander Perez; Christopher Michael Haid; Forrest W. Pieper;

Applicant: Massachusetts Institute of Technology