The 3D printing technology has moved well beyond prototyping at small scale. It is about to usher in Industrial Revolution 2.0.

Earlier this year, we revealed a patent application from Disney about an ultra-fast 3D printing technology. Boeing is planning to 3D print aircrafts parts with its futuristic technology to 3D print objects while levitating in space. Disney has developed technology to even 3D print fabric based stuff toys.

We discovered a recent patent application from Xerox gives us an indication of how 3D manufacturing is going to disrupt mass production.

Digital 3D manufacturing, also known as digital additive manufacturing, is a process of making a 3D solid object of virtually any shape from a digital model. 3D printing is distinguishable from traditional object-forming techniques, which mostly rely on the removal of material from a work piece by a subtractive process, such as cutting or drilling.

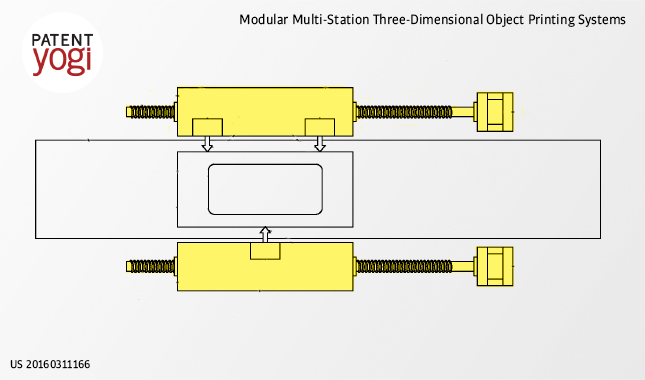

3D printing systems have been developed that have multiple processing stations. Each station is configured to perform different processes involved in manufacturing a finished 3D object. For example, planarizing, curing or cooling between ejecting material layers or after completing a printed object.

Such multi-station 3D printing systems often comprise a track that guides a cart from one processing station to another. The cart rides along the track to convey a substrate between processing stations. The cart is moved along the track by a motor such as a linear synchronous motor (LSM) or a linear induction motor (LIM). LSM and LIM technology allows for quick and reliable motion of the cart between stations, but it does not provide enough force and resilience to operate under the various loads that the cart may encounter at the various processing stations.

Xerox has developed a modular multi-station 3D object printing system for precision control of the cart carrying the object. The system takes advantage of the speed and flexibility of LSM and LIM technology while also providing accurate motion at processing stations that is resilient against weight, speed, and load changes associated with the variety of processing steps required to manufacture a finished 3D object.

Specifically, each processing station includes an additional precision track to securely engage the cart and move it precisely when required.

For example, such a printing system may include eight processing stations, including six printing stations, a planarizing station, and a curing station. Each printing station may have a printhead configured to eject a material onto a substrate. The planarizing station may have a planarizer configured to planarize a substrate. The curing station may have a curing or cooling device configured to cure or cool the substrate. The particular combination and placement of processing stations is adaptable according to the process steps that are performed to manufacture a finished three-dimensional object.

The patented printing system could automate mass manufacturing using 3D printing.

Publication number: US 20160311166

Patent Title: Modular Multi-Station Three-Dimensional Object Printing Systems

Publication date: 27 Oct 2016

Filing date: 22 Apr 2015

Inventors: Richard A. Campbell;