MIT’s Self-Assembly Lab has developed new materials and methods, which make it possible to easily provide complex 3D shaped materials.

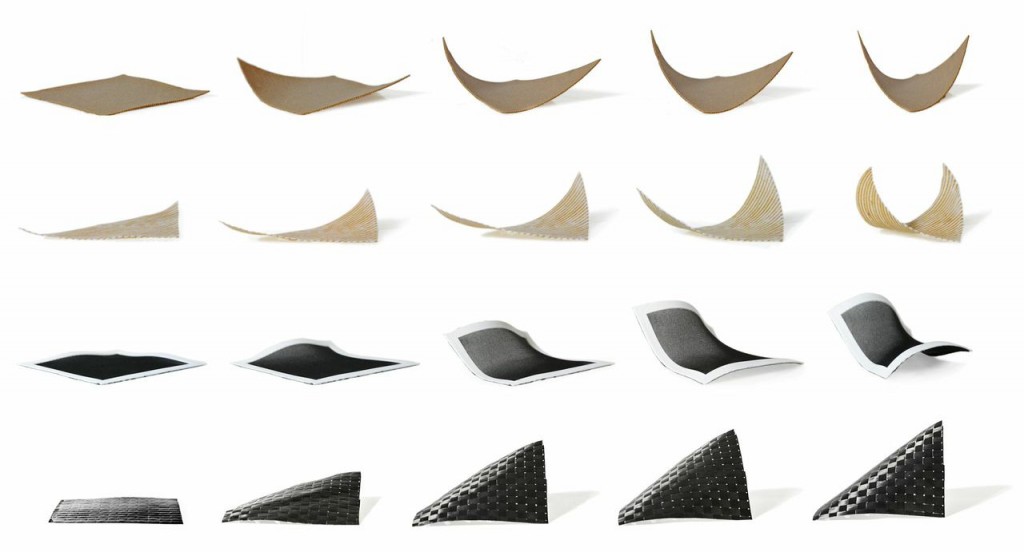

The invented technique is capable of producing predictable and unique geometric structures from traditionally passive, flat materials to thereby open up new opportunities for a variety of products and industrial manufacturing processes.

Many industries require precisely shaped materials to meet aesthetic and functional needs. For example, 1) in sports and physical fitness, complex 3D structures for sportswear and equipment are required from a performance and aesthetic perspective. 2) In the related world of fashion design, intricate patterns using pleating and complex stitching details are often utilized. When designing clothing, footwear and other accessories, the materials must be formed into shapes having a complex curvature to provide a variety of wearers with a proper fit. 3) Interior design involves furniture and other products that typically require manual assembly, molding, pleating, tufting, knotting, complex stitching, and other intricate detailing processes. Further, textile-based complex and 3-dimensional interior partitions and other wall treatments are commonly used. 4) In the medical and health fields, compression garments with various degrees of compression and tension across the body are needed to help circulate blood flow in custom pathways and to provide support.

According to a recent patent from MIT, the MIT has developed new materials and methods which make it possible to easily provide complex 3D shaped materials. In addition, customization of the manufactured 3D shapes, without increasing or the complexity, skill, and time for producing custom products would be possible. “We can have active textiles that self-transform, but also make it efficient so that it could be feasible to produce these because it’s a minimal amount of time and material to get the textile highly active,” adds designer and computer scientist at MIT, Skylar Tibbits.

Specifically, MIT has invented a method of forming an active self-transformable material comprising providing a flexible base material. An active material is 3D printed on surfaces of the flexible base material in a specific pattern to form a combined structure having a natural shape. The active material is a material that is reactive to exposure to an external stimulus trigger. The flexible base material is non-reactive to the external stimulus trigger, minimally reactive to the external stimulus trigger, or reactive to the external stimulus trigger differently than the active material. The exposure of a portion of the specific pattern of the active material to the external stimulus trigger changes the shape of the combined structure from the natural shape into a predetermined 3-dimensional transformed shape. The video below shows how an entire shoe is created by printing the upper part of a shoe and a sole on a 2D surface of fabric.

The active material is reactive to the external stimulus trigger by swelling or shrinking. The active material has a thermal expansion modulus that causes the active material to shrink or swell upon exposure to a temperature change. The change in the shape of the combined structure from the natural shape into a predetermined 3-dimensional transformed shape is a reversible change. The change in the shape of the combined structure from the natural shape into a predetermined 3-dimensional transformed shape is an irreversible change.

The invented technique is capable of producing predictable and unique geometric structures from traditionally passive, flat materials to thereby open up new opportunities for a variety of products and industrial manufacturing processes. By reducing the manual labor, time and skill required to form materials into complex shapes, the present techniques provide significant efficiencies and manufacturing opportunities. Similarly, by introducing a new method for creating highly active self-transforming materials, entirely new products can be imagined that would not have been previously possible.

Moreover, the invented active self-transforming materials can also be designed to create dynamic performance increase -including aerodynamics, moisture control, temperature control or other properties which provide highly dynamic complex shapes/textures/patterns that may create a competitive advantage. For example, by controlling the shape and resultant flexibility/stiffness and actuation of the transforming material, a dynamic combined structure surface can transform on an athlete to increase or decrease aerodynamic resistance or breathability for higher performance. Similarly, the transformable materials can dynamically apply pressure in various points of the body to increase and control blood-flow, and form active compression garments for athletic and medical benefits. Such transformable materials can also be used to form dynamic support for enhanced strength, walking or other physical maneuvers (i.e., a tunable textile exoskeleton). Likewise, the transformable materials can provide dynamic apparel or footwear for different environments, dynamic body conditions or varied user performance (e.g., running vs. walking etc.). Using the present transformable materials, environmentally adaptive clothing and footwear can be provided wherein, for example, footwear can be designed to automatically pull together and become more water resistant when exposed to moisture, or to expand and allow more airflow if the foot becomes too hot. The transformable materials could also be used in providing structures like shoe soles, tires, and other structures provided with a grip-like surface to change their grip in response to moisture (e.g., a shoe sole or tire that can change its tread/grip as it gets wet).

Publication number: US 20160340826

Patent Title: Active Self-Transformable Textiles

Publication date: 24 Nov 2016

Filing date: 23 May 2016

Inventors: Skylar JE Tibbits; Athina Papadopoulou; Christophe Guberan;

Original Assignee: Massachusetts lnstitute of Technology