No business wants to fall behind the competition, and one way to stay ahead is to constantly update your production line with the latest tools. But how do you go about introducing new tools into a production line without disrupting the flow or quality of your products? Here are a few tips:

Do your Research

Thorough research is pivotal to making sure that the new tools you’re introducing will be an improvement on the current ones. Several factors should be considered, including cost efficiency, and compatibility with the rest of the production line. Once you’re confident that the new tools are worth investing in, you can move on to the next step.

Make a Plan

Make a plan for how you’re going to introduce the new tools into the production line. You need to consider the existing workflow and make sure that the new tools will fit seamlessly into it. Consider your employee’s training needs as well as how they will adjust to new tools.

Implement the Plan

After a thorough investigation and creating a roadmap, now is the time to implement your plan and introduce the new tools into the production line. This is where you need to be careful and ensure that everything goes smoothly. During this period, focus on the quality of your products as well as the performance of your employees.

By following these steps, you can successfully introduce new tools into your production line without disrupting the flow or quality of your products.

Some New Tools That May Interest You

In an effort to improve the efficiency of your production line, one tool that you may want to consider introducing into your production line is a CNC machine. CNC machines are computer-controlled machines that you can use to create custom parts and components.

These machines are designed to automate the manufacturing process and can produce parts with a high degree of accuracy. If you’re looking for a way to improve the efficiency of your production line, then a custom CNC machine is definitely worth considering. However, before you invest, it’s important to do your research and ensure that the machine will be compatible with the rest of your production line.

In addition to custom CNC machines, there are many other tools that you may want to consider introducing into your production line. These include:

3D printers

3D printers are becoming increasingly popular in the manufacturing industry due to their ability to create complex parts and components. 3D printers work by building up layers of material to create the desired shape. This technology is still in its early stages, but it has the potential to revolutionize the manufacturing industry.

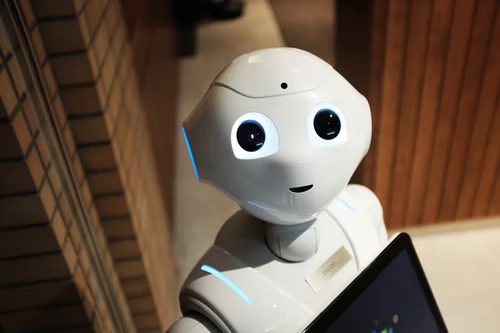

Robots

Robots are another tool that is becoming increasingly popular in the manufacturing industry. Robots can work autonomously and can be programmed to carry out a variety of tasks. They are typically used for repetitive tasks such as welding or painting.

These are just a few new tools that you may want to consider introducing into your production line. New tools can help keep your business ahead of the competition and improve the efficiency of your production line. By doing your research and making sure that the new tools are compatible with the rest of your production line, you can successfully update your production line without disrupting the flow or quality of your products.