Although 3D printing technology is commonly thought of as a new concept, it has actually been around for more than 30 years. The U.S. Army Corps of Engineers (USACE) is at the forefront of developing 3D printing technologies for rapid construction of buildings for a range of military and civilian operations. However, a significant limiting factor for 3D construction projects has been the requirement to construct buildings of concrete rather than cement. Cement is a homogeneous mixture that does not clog the machinery, whereas concrete is a non-homogeneous mixture that has the tendency to clog the machinery. Concrete composition, therefore, is not suitable for 3D printing.

US army has developed and patented a printable concrete composition that also provides the required structural strength.

PATENTED TECHNOLOGY

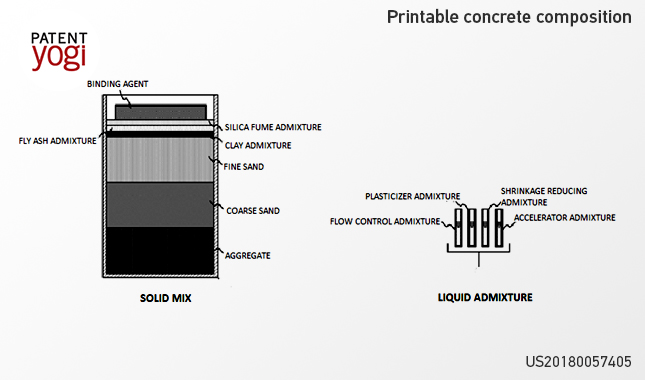

The printable concrete composition developed by US army is made from a combination of three major elements comprising of solid mix, water, and liquid admixture.

The solid mix may be transported and combined with other elements directly on-site to form the printable concrete composition. The solid mix includes a binding agent, an aggregate, coarse sand, fine sand, a clay admixture, a fly ash admixture, and a silica fume admixture. The Aggregate, coarse sand, and fine sand are present in equal proportions, whereas, clay admixture and fly ash admixture are present in amounts approximately 8% and 5% respectively, providing increased flow-ability and reduced set time for printable concrete composition.

The liquid admixture includes a flow control admixture, a plasticizer admixture, a shrinkage reducing admixture and an accelerator admixture. The flow control admixture improves the flow and pumping of printable concrete composition at high pressures. The plasticizer admixture allows a reduction in the amount of water used in printable concrete composition, whereas, the shrinkage reducing admixture reduces cracking and shrinkage of composition during drying.

ADVANTAGES

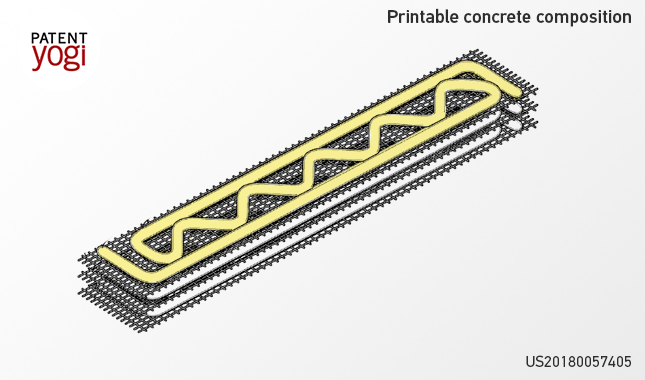

Printable concrete composition allows 3D printing for constructing building components that require high strength. Once the printable concrete composition is prepared, a user may print a structure without further modification of the composition. Further, the user may embed mesh between layers of the printable concrete composition to reinforce or stabilize the structure.

WHAT IS YOUR TAKE?

So what do you think about this technology from US army? Does US army plan to 3D print buildings on Mars? Let us know in the comment section.

Did you know Boeing patented technology to 3d print objects while levitating in space?

Publication Number: 20180057405

Patent Title: Printable concrete composition

Publication date: 1 Mar 2018

Filing date: 16 Dec 2016

Inventors: Ghassan Al-Chaar; Michael Patrick Case; Gerald R. Northrup; Megan A. Kreiger; Bruce A. MacAllister; William Jacob Wagner

Original Assignee: United States of America as Represented by The Secretary of The Army